3D trussgirder is up-to-date rebar design used in modern building construction. 3Dtruss girder will be assembled with roll formed steel deck to be as combinedtemplate for site pouring. This kind of construction method reduces too muchsite rebar binding works, raises working efficiency and shortened constructionperiod. Stress mode of truss girder is reasonable and so provides larger steeldeck rigidity, usually no need temporary support.

II Description of 3D Truss GirderWelding Machine

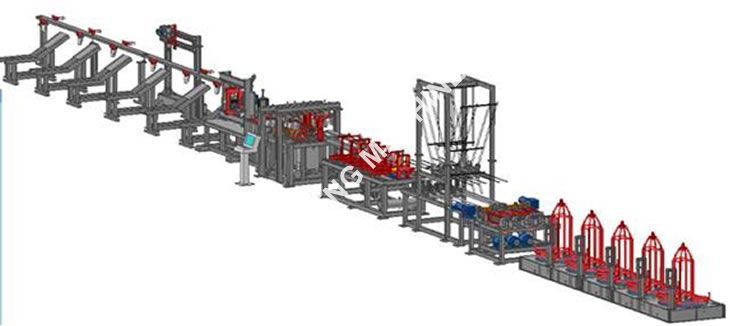

3D trussgirder welding machine is a full automatic production line for produced 3Dtruss girder by three pieces ribbed and two pieces round rebar in reels.

3D trussgirder welding machine is comprised of reel rebar pay-off, rebar straightening,truss rebar bending, welding, cutting and stacking sections.

The wholeproduction line is operated by only one operator. Production speed can reach18m/min.

Characteristics

● The plant is controlled with a system which is reliable, powerful and flexible and controls all the functions of the machine and allows an easy interface with the operator. The main computer has a diagnostic system which allows an immediate check of all the signals emanating from the machine.

● All the axis parameters, machine times and speeds are adjustable from the computer.

● The programming is quick and easy so as to be as user friendly to the operator as possible.

● The welding is controlled by units which allow the operator to adjust and change the periods and the power relative to the production at hand.

● All the power apparatuses for driving the motors and all other functions are mounted in the electronic switching cabinets; all the signal lights and the various commands are found on the cabinets.

● The operator controls the plant through the electronic control stations which are positioned appropriately.

3D trussgirder is up-to-date rebar design used in modern building construction. 3Dtruss girder will be assembled with roll formed steel deck to be as combinedtemplate for site pouring. This kind of construction method reduces too muchsite rebar binding works, raises working efficiency and shortened constructionperiod. Stress mode of truss girder is reasonable and so provides larger steeldeck rigidity, usually no need temporary support.

II Description of 3D Truss GirderWelding Machine

3D trussgirder welding machine is a full automatic production line for produced 3Dtruss girder by three pieces ribbed and two pieces round rebar in reels.

3D trussgirder welding machine is comprised of reel rebar pay-off, rebar straightening,truss rebar bending, welding, cutting and stacking sections.

The wholeproduction line is operated by only one operator. Production speed can reach18m/min.

III Main Technical Data of 3D Truss Girder WeldingMachine

Item | Unit | Data |

Pay-off capacity | kg | 1500 |

Pay-off quantity | pcs | 5 |

Straightening speed | m/min | 30 |

Rebar feeding motor power | kW | 3.7X5 |

Straightening motor power | kW | 7.5X3 |

Truss rebar forming motor power | kW | 7.5 |

Welding transformer power | KVA | 125X2 |

Hydraulic station motor power (for cutting) | kW | 15KW |

Hydraulic pressure | MPa | 25 |

Rebar bending motor power | kW | 7.5 |

Stacking chain moving motor power | kW | 3 |

Stacking rack elevating motor power | kW | 3 |

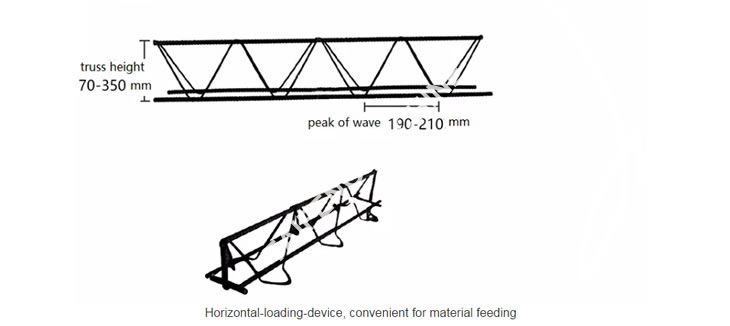

Truss rebar bending pitch | mm | 200 |

Truss girder height | mm | 70-300 |

Truss girder width | mm | 60-90 |

Longitudinal rebar diameter | mm | 5-12 |

Truss rebar diameter | mm | 4-7 |

Truss girder length | m | 2.4~12 |

Production speed | m/min | 0~18 |

Pneumatic pressure | MPa | 0.6 |

Air consumption | m3/min | 1.8 |

IV Steel truss production line

No | Part of the equipment | quantity |

1 | Wire rod steel wire frame | 5sets |

2 | steel-bar butt welder | 1set |

3 | flattening machine | 1set |

4 | Storage machine | 2sets |

5 | Terminal flattening machine | 1set |

6 | The pressing machine | 1set |

7 | Welding machine | 1set |

8 | hauling machine | 1set |

9 | Shearing machine | 1set |

10 | Automatic collecting mechanism | 1set |

11 | electrical control system | 1sets |

12 | operating system | 1ses |

13 | Manual, spare parts and tools | 1sets |